HPS-N series

2022-12-18 Click:

Imported PES filter membrane is adopted in the product as filter media. The product is produced by overall structure sweat welding. The filter element is produced through optimum filter membrane matching mode, thereby the product has higher pollutant containing ability and longer service life, which is suitable for terminal filtration of high viscosity material fluid.

Features:

Features:

●The filter membrane is hydrophilic with absolute filtration accuracy;

● Low protein adsorption performance;

● High pollutant containing ability;

● Long service life and economic use;

Typical applications:

● Sterile filtration of vaccine;

Typical applications:

● Sterile filtration of vaccine;

●Sterile filtration of blood products;

● Sterile filtration of raw material medicine, injections and other drugs;

● Filtration of draft beer;

Quality assurance:

● ISO9001: 2008 guaranteed quality management system;

● Traceability management system of each filter;

● Filter elements are flushed and pass integrity test before filter elements are left from the factory;

● The batch passes through bacterial challenge test for confirming 100% bacteria interception ability;

Biological safety:

Biological Safety: The product materials comply with USP in-vivo VI-121 ℃ plastic biological response test.

Endotoxin: <0.25EU/ml;

Cleanliness: The product is in line with 2010 GMP requirements on injection of particles;

Readily oxidizable substance: the substance should be in line with 2010 GMP test requirements of particle contents in injections after water rinsing for 2000ml;

TOC/conductivity: after the product is flushed with 20L injection water at 25 ℃ (10〃) . It is in line with requirements of 2010 GMP on total organic carbon contents and conductivity in injection water.

Filter element material composition:

Filter membrane | PES filter membrane |

Diversion material | Polypropylene |

Outer shell | Polypropylene |

Seal ring | Please see Filter Element Model Selection Table |

Integrity test:

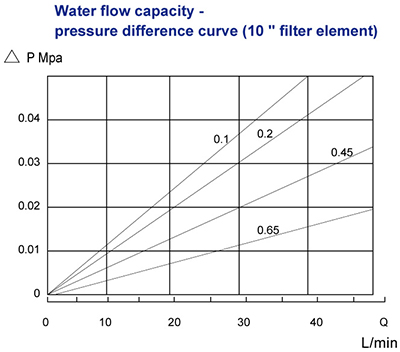

Aperture(um) | 0.1 | 0.2 | 0.45 | 0.65 |

The lowest bubbling point in pure water(MPa) | ≥0.48 | ≥0.34 | ≥0.23 | ≥0.14 |

Main application technical indicators:

Maximum operating temperature | 85℃/0.1MPa |

Maximum operating pressure difference | 0.42MPa/25℃ |

Recommended operating pressure difference | 0.1-0.2MPa/25℃ |

Maximum back-pressure difference | 0.2MPa/25℃ |

Effective filtration area (10 inches) | ≥0.6㎡ |

Forward online steam sterilization (135 ℃) | 30min/time |

Disinfection by Disinfection cabinet (121 ℃) | 30min/time |